PERFECT SOLUTION

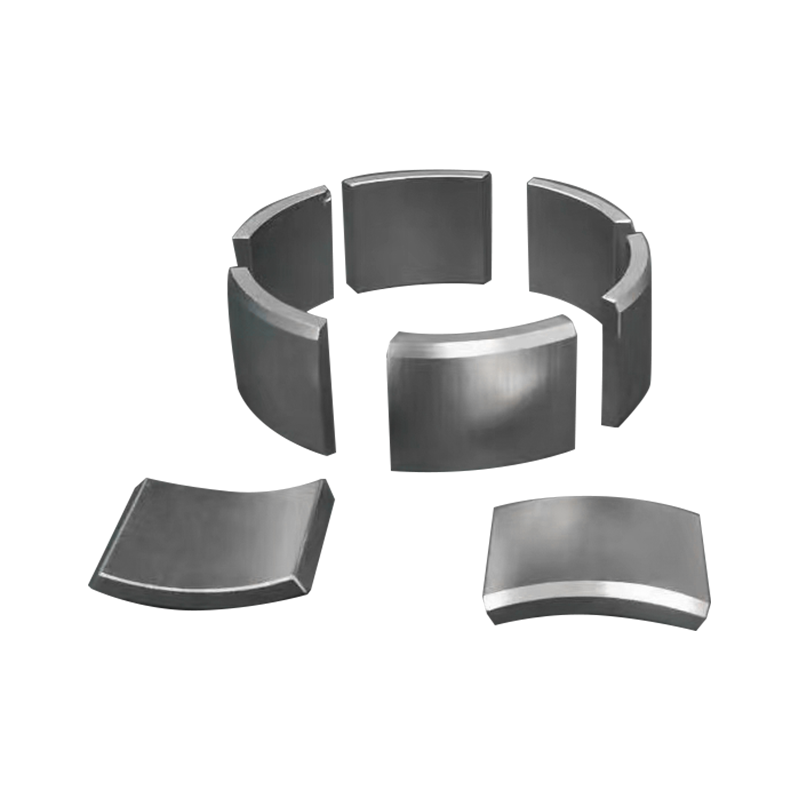

From instrumentation to home appliances, our magnetic tiles are a premium choice for reliable, efficient motor solutions.

Let’s get more informationsThe products are widely used in many fields, such as instrument, magnetic drive, nuclear magnetic resonance, automobile motor, treadmill motor, sewing motor, massager motor, household appliance motor, aviation and navigation, medical equipment and so on.

Introduction:The Cleaning Machine Magnetic Tiles involves the production and provision of high-quality magnetic components tailored for various applications. These Cleaning Machine Magnetic Tiles play pivotal roles in numerous industries, including automotive, electronics, and renewable energy. Manufacturing Process:The Cleaning Machine Magnetic Tiles are meticulously crafted through advanced manufacturing techniques. The process begins with the formulation of raw materials, typically neodymium iron boron (NdFeB) powder, along with additives to enhance magnet performance. The materials are then compacted using a dry pressing method under controlled conditions, ensuring precise shaping and density. Subsequently, the compacted segments undergo sintering at high temperatures, followed by machining to achieve the desired dimensions and surface finish.Properties:These Cleaning Machine Magnetic Tiles boast nice magnetic properties attributed to their isotropic nature. They exhibit great magnetic characteristics in all directions, enabling versatile applications. With high coercivity and remanence, these Cleaning Machine Magnetic Tiles deliver good magnetic strength and stability. Their special shapes allow for efficient flux concentration and distribution, improving performance in diverse environments. Furthermore, they exhibit nice resistance to demagnetization, ensuring a prolonged operational lifespan.Applications:The versatility of the Cleaning Machine Magnetic Tiles renders them indispensable across various industries. In the automotive sector, they find applications in electric vehicle drivetrains, power steering systems, and hybrid propulsion systems, contributing to enhanced efficiency and performance. In the electronics industry, these magnets are utilized in sensors, actuators, and loudspeakers, facilitating precise control and signal processing. Additionally, they play crucial roles in renewable energy technologies such as wind turbines and electric generators, promoting sustainable power generation.Moreover, the continuous advancements in material science and manufacturing technologies contribute to the ongoing evolution of the Cleaning Machine Magnetic Tiles. Research and development efforts focus on enhancing magnet performance, durability, and cost-effectiveness to meet the ever-growing demands of modern applications. Collaborations between industry important and academic institutions drive innovation, nice to the discovery of novel materials and fabrication techniques. As a result, the future holds promising prospects for further improvements in magnet design, enabling even more efficient and versatile solutions for tomorrow's technological challenges. By staying at the important area of these developments, manufacturers and users alike can harness the full potential of the Cleaning Machine Magnetic Tiles to drive progress and innovation across a wide range of industries.Benefits:The utilization of the Cleaning Machine Magnetic Tiles offers numerous benefits to end-users. Their high magnetic strength enables compact and lightweight designs without compromising performance. Moreover, their nice stability ensures reliable operation under demanding conditions, reducing downtime and maintenance costs. The tailored shapes of these magnets optimize flux density and distribution, enhancing overall system efficiency. Additionally, their compatibility with various manufacturing processes facilitates seamless integration into existing applications, promoting innovation and competitiveness.Conclusion:In conclusion, the Cleaning Machine Magnetic Tiles represent good magnetic solutions with good applications across diverse industries. Their advanced manufacturing process, coupled with good properties and tailored shapes, positions them as important components in modern technologies. By harnessing the capabilities of these magnets, businesses can achieve enhanced performance, efficiency, and sustainability in their products and systems.

Introducing our great innovation, the Electric Wheelchair Magnetic Tiles, a change in magnet technology. Crafted with precision and engineered for nice, this Electric Wheelchair Magnetic tile embodies nice quality and performance. Designed in a distinctive arc shape, it promotes efficiency and power, setting new standards in motor technology.With its advanced ferrite composition, this Electric Wheelchair Magnetic Tile boasts nice strength and durability, ensuring longevity and reliability in even a hard application. The Electric Wheelchair Magnetic Tiles's unique design allows for seamless integration into various motor systems, enhancing overall performance and efficiency. No matter what kind of electric wheelchair it is used on, the Electric Wheelchair Magnetic Tiles delivers good results.One of its key advantages lies in its ability to optimize energy conversion, reducing energy loss and improving output. This translates to improved productivity and cost-effectiveness, making it a nice choice for engineers and manufacturers worldwide. Additionally, its streamlined design reduces friction and heat generation, further enhancing operational efficiency and extending equipment lifespan.Beyond its technical prowess, this Electric Wheelchair Magnetic Tile embodies versatility, adapting effortlessly to diverse environments and operating conditions. From high-speed machinery to heavy-duty equipment, it remains steadfast, delivering consistent performance under pressure. Its compact size and lightweight construction offer flexibility in design, enabling compact and space-efficient solutions without compromising power or performance. Innovative design features, such as its arc-shaped profile and precise magnetization, contribute to enhanced efficiency and power density. By improving magnetic flux density within a compact form factor, it enables the development of smaller, lighter, and more efficient motor systems. This not only saves space but also reduces overall system weight, a critical consideration in applications where weight is a limiting factor.The Electric Wheelchair Magnetic Tiles facilitate seamless integration with advanced control systems and electronics, enabling precise speed control and torque management. Its compatibility with modern motor control technologies enhances system performance, responsiveness, and energy efficiency, unlocking new possibilities for innovation and optimization across various industries. Moreover, the Electric Wheelchair Magnetic Tiles are engineered to withstand bad conditions, ensuring consistent performance in harsh environments. Its durable construction and robust materials make it resistant to corrosion, temperature fluctuations, and mechanical stress. Whether operating in arduous industrial settings or exposed to outdoor elements, this magnet maintains its integrity, guaranteeing reliable operation under any circumstances.Furthermore, the Electric Wheelchair Magnetic Tiles prioritizes sustainability, contributing to greener and more eco-friendly operations. By optimizing energy usage and reducing waste, it aligns with the growing demand for environmentally responsible technologies. Its eco-conscious design underscores our commitment to innovation that not only meets but exceeds industry standards. Manufactured using eco-friendly processes and materials, it reduces environmental impact without compromising performance or quality. By choosing the Electric Wheelchair Magnetic Tiles, businesses not only benefit from good performance but also contribute to a greener, more sustainable future.In conclusion, the Electric Wheelchair Magnetic Tiles represents a nice of magnet technology, combining good performance, durability, and versatility. With its innovative design and good capabilities, it drives efficiency, productivity, and sustainability across various industries. Experience the power of innovation with the Electric Wheelchair Magnetic Tiles – where good meets ingenuity.

Floor Washing Machine Magnetic Tiles are innovative magnetic components engineered for good performance across various applications. Crafted through advanced sintering techniques, these magnets boast nice strength and durability, setting a new standard in magnetic technology.Characterized by their arc segment tile design, these Floor Washing Machine Magnetic Tiles offer a myriad of advantages. Their specialized construction ensures nice magnetic flux distribution, resulting in good magnetic properties such as high coercivity and nice resistance to demagnetization. This ensures reliable and stable performance even under challenging operating conditions. Another key advantage lies in their thermal stability. These Floor Washing Machine Magnetic Tiles exhibit nice resistance to high temperatures, making them suitable for applications where heat dissipation is a concern. This thermal resilience ensures sustained performance even in demanding environments, safeguarding critical operations.One of the great features of Floor Washing Machine Magnetic Tiles is their versatility. Designed to meet diverse industrial needs, Widely used in a variety of floor washing machine brands, and more. Whether used in motors, sensors, magnetic separators, or magnetic resonance imaging (MRI) systems, these Floor Washing Machine Magnetic Tiles deliver consistent and efficient magnetic field generation. Furthermore, Floor Washing Machine Magnetic Tiles offer nice cost-effectiveness compared to alternative magnetic materials. Their production efficiency, coupled with their long operational lifespan, translates to significant savings for users alike. This affordability without compromising performance makes them an attractive choice across industries.Floor Washing Machine Magnetic Tiles' robust construction enhances longevity, making them a cost-effective solution for long-term use. With fewer maintenance requirements, they offer extended service life, reducing downtime and maintenance costs for users.Floor Washing Machine Magnetic Tiles are renowned for their environmental friendliness. Manufactured using sustainable materials and processes, they comply with stringent environmental regulations, contributing to a greener and more sustainable future. In addition to their primary applications, these magnets also play a crucial role in emerging technologies such as magnetic levitation systems and magnetic bearings. Their precise control over magnetic fields enables the realization of innovative solutions for transportation, energy storage, and beyond, driving the advancement of modern engineering.Furthermore, their compact size and lightweight design make them easy to integrate into various applications without compromising on performance. This makes them ideal for space-constrained environments where efficiency and reliability are good. The precision engineering behind Floor Washing Machine Magnetic Tiles ensures consistent quality and reliability batch after batch. Their tight tolerances and uniform magnetic properties guarantee predictable performance, enabling seamless integration into complex systems and assemblies.In essence, Floor Washing Machine Magnetic Tiles stand as a testament to ingenuity and engineering well. With their nice combination of performance, reliability, and versatility, they continue to redefine possibilities in the realm of magnetic technology, powering progress across diverse industries and applications. In conclusion, Floor Washing Machine Magnetic Tiles represent an important area of magnetic technology, combining good performance, durability, and versatility. Whether powering automotive components, enhancing electronic devices, or driving renewable energy solutions, these Floor Washing Machine Magnetic Tiles excel across a myriad of applications, ensuring nice performance and reliability.

Introduction:Introducing our nice line of Fitness Equipment Magnetic Tiles, specifically engineered with Ferrite Magnet technology to deliver great performance across a myriad of applications. Crafted with meticulous attention to detail, these magnets epitomize strength, durability, and versatility. Fitness Equipment Magnetic Tiles boast a sleek, yet robust exterior design, reflecting their nice performance capabilities. With a clean and polished finish, these Fitness Equipment Magnetic Tiles exude a sense of precision engineering, instilling confidence in their reliability and durability. Whether incorporated into industrial machinery or consumer electronics, their visually appealing appearance adds a touch of sophistication to any application.Various Specifications:We know one size does not fit all, which is why we offer a variety of options to suit your diverse requirements. From different shapes and sizes to specialized coatings, our Fitness Equipment Magnetic Tiles can be seamlessly integrated into your designs. Our team of experts strives to ensure every magnet exceeds your expectations and delivers outstanding performance in any environment.Great Performance:At the core of our Strong Custom Magnets is Ferrite Magnet technology, renowned for its good magnetic properties and reliability. With good coercivity and high resistance to demagnetization, these Fitness Equipment Magnetic Tiles provide steadfast magnetic strength over prolonged periods, making them ideal for demanding applications where consistency is good. Every detail of Fitness Equipment Magnetic Tiles is meticulously crafted with precision engineering techniques. From the alignment of magnetic domains to the coating thickness, each Fitness Equipment Magnetic Tile is carefully calibrated to ensure good performance and longevity. This dedication to precision not only enhances the magnets' functionality but also sets a standard of nice in the industry.Sustainable Manufacturing:Furthermore, our commitment to sustainability is inherent in every aspect of our manufacturing process. We prioritize eco-friendly materials and efficient production methods to reduce waste and reduce our environmental footprint. By choosing our Fitness Equipment Magnetic Tiles, you're not only investing in good performance but also contributing to a greener future.Comprehensive Support:In addition to our Fitness Equipment Magnetic Tiles offerings, we also offer comprehensive support services to ensure seamless integration and ongoing maintenance. Our team of technical experts is on hand to provide guidance and assistance at every stage of your project, from initial design consultation to post-installation support. Moreover, our commitment to quality extends beyond product performance. We adhere to rigorous manufacturing standards and employ good processes to ensure that each magnet upholds good levels of reliability and longevity. Whether you require large-scale production or small-batch prototypes, our agile manufacturing capabilities enable us to deliver on time, every time.Driving Progress:Whether you're revolutionizing telecommunications infrastructure or enhancing consumer electronics, our Fitness Equipment Magnetic Tiles provide the backbone for innovation. Trust in our expertise and experience to elevate your products to new heights of performance and reliability. Unlock the potential of magnetic technology with our Fitness Equipment Magnetic Tiles today.Conclusion:In conclusion, when it comes to Fitness Equipment Magnetic Tiles, trust in our expertise, reliability, and commitment to nice. With Ferrite Magnet technology at the core, backed by many options and good support services, we are your trusted partner for all your magnetic needs. Experience the difference with our Fitness Equipment Magnetic Tiles and unlock a world of possibilities for your next project.

The Lawn Mower Magnetic Tiles stands nice engineering, poised to redefine the landscape of electric propulsion systems. Crafted with precision and innovation, this magnetic Lawn Mower Magnetic Tiles embodies nice performance, efficiency, and reliability, catering to the diverse needs of modern industries.At its core, the Lawn Mower Magnetic Tiles harnesses the intrinsic properties of ferrite material, meticulously processed through advanced arc magnetization techniques. This intricate process ensures nice magnetic alignment, empowering the magnet to deliver robust performance across a myriad of applications.In the realm of electric motors, efficiency reigns well. Herein lies the forte of the Lawn Mower Magnetic Tiles. By virtue of its good magnetic properties, including high coercivity and nice resistance to demagnetization, this magnet facilitates seamless power transmission within electric motors, reducing energy losses and promoting operational efficiency.Versatility defines the essence of the Lawn Mower Magnetic Tiles. Its adaptability shines through, bolstering the performance of diverse applications with nice precision and reliability.In the pursuit of good, reliability is good. The Lawn Mower Magnetic Tiles undergoes stringent quality control measures to guarantee consistency and durability. Each magnet is meticulously crafted to exacting standards, undergoing rigorous testing to validate its performance and longevity. This commitment to quality instills confidence in users, fostering long-term partnerships built on trust and reliability.Beyond its technical specifications, the Lawn Mower Magnetic Tiles embodies a commitment to sustainability and environmental stewardship. By facilitating energy-efficient operations and reducing reliance on fossil fuels, it aligns seamlessly with global efforts to combat climate change and promote a cleaner, greener future. As industries worldwide transition towards more sustainable practices, the Lawn Mower Magnetic Tiles stands as a beacon of progress, driving innovation while safeguarding the planet for future generations.With sustainability in an important area of technological advancements, the Lawn Mower Magnetic Tiles emerges as a beacon of eco-conscious engineering. By enabling energy-efficient operations and reducing carbon footprints, it contributes significantly to the global drive towards a greener future.Reliability is non-negotiable in demanding industrial environments, and the Lawn Mower Magnetic Tiles surpasses expectations with its robust construction and enduring performance. Engineered to withstand good temperatures, vibrations, and operational stresses, it ensures uninterrupted functionality even in hard conditions, thereby enhancing operational uptime and reducing maintenance costs.Innovation knows no bounds with the Lawn Mower Magnetic Tiles. Its seamless integration with emerging technologies such as renewable energy systems, and automation solutions underscores its pivotal role in shaping the future of mobility, sustainability, and industrial progress.The Lawn Mower Magnetic Tiles isn't just a component; it's a catalyst for transformation. Its nice magnetic prowess powers the aspirations of industries worldwide, driving efficiency, sustainability, and innovation to new heights.In essence, the Lawn Mower Magnetic Tiles represents more than just a technological advancement; it symbolizes a shift towards a more sustainable, efficient, and prosperous future. With its unparalleled performance, reliability, and commitment to sustainability, it paves the way for a new era of electrification and industrial progress. As industries embrace the transformative potential of electric propulsion systems, the Lawn Mower Magnetic Tiles stands ready to power the innovations of tomorrow, driving us towards a brighter, more sustainable future. In conclusion, the Lawn Mower Magnetic Tiles represents a paradigm shift in magnetic technology, offering good performance, efficiency, and reliability across diverse applications. As industries embrace the era of electrification and sustainability, this magnetic marvel stands ready to propel them toward a future defined by progress and possibility.

Introducing our product: Industrial Fan Magnetic Tiles. Designed to change industrial ventilation systems, these innovative tiles boast nice efficiency and versatility, catering to the diverse needs of modern manufacturing facilities.Crafted with precision engineering, Industrial Fan Magnetic Tiles seamlessly integrate into existing fan units, enhancing airflow management with effortless installation. Their magnetic design ensures a secure fit, eliminating the need for complex mounting hardware and reducing downtime during maintenance.Unleash the power of customization with Industrial Fan Magnetic Tiles. Engineered for adaptability, these tiles offer adjustable airflow patterns, allowing users to optimize ventilation according to specific workspace requirements. From large-scale factories to compact workshops, our tiles deliver consistent performance across various environments.With Ferrite Magnet as the core material, Industrial Fan Magnetic Tiles excel in withstanding the demanding conditions of industrial environments. Resistant to corrosion and wear, these tiles maintain their integrity over time, Invest in peace of mind with Industrial Fan Magnetic Tiles' robust reliability and low maintenance requirements. Built to withstand harsh industrial environments, these tiles undergo rigorous testing to ensure long-term durability. With less upkeep, you can focus on your core operations, confident in the dependable performance of your ventilation system.Experience uninterrupted productivity with our robust and reliable solution. Industrial Fan Magnetic Tiles are built to withstand the rigors of industrial operations, featuring durable materials that resist corrosion and wear. Say goodbye to costly replacements and hello to long-term savings. Unlock endless possibilities with the modular design of Industrial Fan Magnetic Tiles. Whether you're expanding your facility or reconfiguring workspace layouts, these tiles adapt effortlessly to evolving needs. With their modular construction, you have the flexibility to scale your ventilation system as your business grows, ensuring continued productivity and profitability.Improve operational efficiency with the intelligent features of Industrial Fan Magnetic Tiles. Equipped with advanced airflow control mechanisms, these tiles enable precise regulation of ventilation, promoting good working conditions and enhancing employee comfort. Experience good convenience with Industrial Fan Magnetic Tiles' user-friendly interface and intuitive controls. Whether you're adjusting airflow direction or fine-tuning ventilation settings, our intuitive system simplifies operation, empowering your team to optimize performance with ease.Experience the seamless integration of efficiency and sustainability with Industrial Fan Magnetic Tiles. Engineered with eco-conscious design principles, these tiles optimize energy consumption without compromising performance. By promoting airflow efficiency, they contribute to reduced energy costs and environmental impact, aligning with your organization's sustainability goals.Elevate your facility with our comprehensive support services. From initial consultation to post-installation maintenance, our team is committed to delivering good customer care every step of the way. We understand the importance of uptime in industrial settings and strive to minimize disruptions through timely assistance and proactive solutions.Join the industrial innovation with Industrial Fan Magnetic Tiles. Transform your ventilation infrastructure with a solution that combines nice technology, reliability, and good performance. Change your workspace today and unlock the full potential of Industrial Fan Magnetic Tiles. From enhanced airflow management to eco-friendly design, these tiles redefine the standards of industrial ventilation. Invest in innovation, invest in Industrial Fan Magnetic Tiles, and propel your business towards a brighter, more sustainable future.

Introducing Electric Door Magnet Tiles, crafted with high-quality Ferrite Magnet material, these innovative tiles are engineered to elevate your door experience. Designed for durability and reliability, Electric Door Magnet Tiles offer nice convenience and functionality for a seamless door operation.At the core of our product lies the good performance of Ferrite Magnet material, ensuring strong magnetic attraction for efficient door closure. Whether it's a residential entrance or a commercial facility, our tiles guarantee secure closure every time, enhancing safety and privacy.Additionally, our tiles are designed to withstand the test of time. Constructed from durable Ferrite Magnet material, they exhibit good resilience against wear and tear, ensuring long-term performance and reliability. With Electric Door Magnet Tiles, you can rest assured that your door system will continue to operate smoothly for years to come, reducing the need for frequent maintenance and replacements.One of the great features of Electric Door Magnet Tiles is their effortless installation process. With a user-friendly design, these tiles can be easily integrated into existing door systems, requiring less time and effort. Say goodbye to complex installations and hello to hassle-free convenience.In addition to their ease of installation, these tiles boast versatile applications. From controlling access to managing temperature zones, Electric Door Magnet Tiles offer a wide range of functionalities to suit various needs. Whether you're looking to enhance security measures or streamline traffic flow, our tiles provide the solution you need.Another notable advantage of Electric Door Magnet Tiles is their compatibility with various door types and sizes. Whether you have a standard-sized entrance or a custom-designed door, our tiles can be tailored to meet your specific requirements. This versatility makes them a good choice for a wide range of residential, commercial, and industrial applications, offering flexibility without compromising performance.Moreover, our commitment to customer satisfaction extends beyond the product itself. With dedicated customer support, we ensure prompt assistance and guidance at every step of the way. Whether you have questions about installation or need troubleshooting advice, our team is here to help, ensuring a smooth experience from start to finish.Our Electric Door Magnet Tiles are engineered with energy efficiency in mind. By providing a reliable mechanism for door closure, these tiles help maintain nice indoor temperatures, reducing the workload on heating and cooling systems. This not only contributes to energy savings but also promotes a more sustainable environment. Furthermore, Electric Door Magnet Tiles are designed with user convenience in mind. Their silent operation ensures less disturbance, making them ideal for environments where noise reduction is crucial, such as libraries, offices, and residential spaces. In conclusion, Electric Door Magnet Tiles stand as a testament to innovation and nice in-door technology. From their energy-efficient design to their durable construction and versatile compatibility, these tiles embody the great of door management solutions. Experience the good convenience and reliability of Electric Door Magnet Tiles and elevate your door experience today. Electric Door Magnet Tiles redefine door technology with their good performance, ease of installation, versatile applications, and nice customer service. Experience the future of door management with Electric Door Magnet Tiles today.

Introducing our proud product: the Curved Neodymium Magnet. Crafted with precision and innovation, these magnets redefine the standards of magnetic technology. What truly sets us apart is our unwavering dedication to innovation. As technology evolves and industries advance, we remain committed to this important area, continuously researching and developing new applications for our Curved Neodymium Magnets. Whether it's pioneering breakthroughs in renewable energy or changing transportation systems, we're committed to pushing the boundaries of what's possible with magnetic technology.The Curved Neodymium Magnet captivates with its sleek, ergonomic design. Its distinctive curve not only enhances aesthetic appeal but also promotes functionality, allowing for versatile applications in various industries. Whether used in engineering marvels or everyday consumer products, these Curved Neodymium Magnets effortlessly blend form with function.What sets the Curved Neodymium Magnet apart is its nice performance. Engineered with very good neodymium, these Curved Neodymium Magnets boast nice magnetic strength, ensuring robust and reliable attraction. Their unique curvature further enhances magnetic flux concentration, optimizing efficiency and effectiveness in countless applications. From magnetic levitation systems to magnetic resonance imaging machines, our magnets empower innovation across diverse fields.In addition to its technical prowess, the Curved Neodymium Magnet offers environmental benefits as well. Manufactured with sustainability in mind, our magnets adhere to rigorous eco-friendly standards throughout the production process. By reducing waste and energy consumption, we ensure that our products not only perform admirably but also contribute to a greener future.But the advantages don't stop there. Our Curved Neodymium Magnets are designed for durability and longevity, with nice resistance to demagnetization and corrosion. This ensures consistent performance over time, even in demanding environments. Additionally, our commitment to quality extends to customization options, allowing clients to tailor magnets to their precise specifications. Whether it's size, shape, or magnetic strength, we work closely with customers to deliver solutions that exceed expectations.Moreover, the versatility of the Curved Neodymium Magnet knows no bounds. Its unique shape allows for more efficient utilization of space, making it ideal for compact designs where traditional magnets may not fit. Whether it's curved surfaces or tight corners, these Curved Neodymium Magnets adapt seamlessly, unlocking new possibilities for engineers and designers alike.Furthermore, our dedication to customer satisfaction is important. With prompt and professional service, we strive to meet the unique needs of every client. From initial consultation to post-purchase support, our team is committed to ensuring a seamless experience every step of the way.In essence, the Curved Neodymium Magnet isn't just a product—it's a symbol of progress. With its nice design, good performance, and unwavering commitment to sustainability and innovation, it's poised to shape the future of countless industries. Join us in harnessing the power of the Curved Neodymium Magnet and unlock a world of endless possibilities. In conclusion, the Curved Neodymium Magnet represents a breakthrough in magnetic technology. With its innovative design, nice performance, and customizable options, it's the ideal choice for any application requiring powerful and reliable magnetic solutions. Join us in embracing the future of magnetism with the Curved Neodymium Magnet.

Introducing our product, the Block Neodymium Magnet – an epitome of strength, precision, and versatility. Crafted with precision engineering, these magnets boast great magnetic power, making them indispensable across various industries. The Block Neodymium Magnets are crafted from a special alloy known as neodymium-iron-boron (NdFeB), renowned for its good magnetic properties. This alloy combines neodymium, iron, and boron to create magnets with nice strength and magnetic performance.Neodymium, a good earth element, provides the magnet with its powerful magnetic field, while iron enhances its magnetic stability and boron helps to improve the material's corrosion resistance. This unique combination results in magnets that exhibit high coercivity, meaning they are highly resistant to demagnetization, and high remanence, indicating strong residual magnetization even after the removal of the external magnetic field.The material's good magnetic properties make it a nice choice for applications requiring high-performance magnets, such as electric motors, generators, magnetic resonance imaging (MRI) machines, and magnetic separators. Additionally, the neodymium-iron-boron alloy allows for the production of magnets in a variety of shapes and sizes, including the block form, which provides versatility and adaptability to diverse applications. This flexibility, coupled with the material's good magnetic strength, durability, and resistance to corrosion, makes the Block Neodymium Magnets a good choice for demanding industrial and commercial applications.One of the great features of our Block Neodymium Magnets is their great durability. Built to withstand good temperatures and corrosive environments, these magnets guarantee long-term reliability and consistent performance, delivering value that stands the test of time. Designed to excel in demanding applications, the Block Neodymium Magnets offer nice coercivity and high remanence, ensuring great performance in even a challenging environment. Their robust construction and good magnetic properties make them ideal for applications such as motors, sensors, magnetic separators, and more.Furthermore, we understand that every application is unique, which is why we offer customizable solutions to meet specific requirements. Whether it's altering dimensions, modifying coating options, or fine-tuning magnetic properties, our expert team is dedicated to tailoring solutions that precisely align with your needs.Our Block Neodymium Magnets stand out for their nice versatility, catering to a wide range of applications with ease. Whether you're in the automotive industry, renewable energy sector, or consumer electronics market, these magnets offer a reliable solution to your magnetic needs. Their compact design and high magnetic flux density make them ideal for space-constrained applications where promoting performance in a limited footprint is crucial. From miniature electronic devices to large-scale industrial machinery, our Block Neodymium Magnets deliver consistent results, driving efficiency and innovation across industries.In addition to their technical prowess, our Block Neodymium Magnets are also environmentally friendly. Constructed from sustainable materials and manufactured using eco-friendly processes, they align with modern sustainability goals without compromising on performance or reliability.Furthermore, our commitment to quality extends beyond product niceness. We prioritize transparency and integrity in all our interactions, fostering long-term partnerships built on trust and mutual respect. With prompt delivery and responsive customer support, we ensure a seamless experience from inquiry to installation.In conclusion, our Block Neodymium Magnets represent more than just a magnetic solution – they embody reliability, versatility, and sustainability, empowering businesses to thrive in a dynamic and competitive landscape. Join countless satisfied customers who have unlocked the full potential of their applications with our nice magnets.

Industry Experience

Export Country

Equipment Quantity

Our motor magnet tiles are innovative, high-quality, customizable, versatile, and customer-focused. They incorporate advanced technology for improved performance and efficiency, while adhering to rigorous quality control standards. We offer tailored solutions to meet specific requirements and provide high-quality customer service through prompt delivery, responsive communication, and technical support.

Our products are widely used in various fields, including instrumentation, magnetic transmission, nuclear magnetic resonance (NMR), automotive motors, treadmill motors, industrial sewing machine motors, household appliances, massagers, garbage processors, medical equipment, and more.

Motor porcelain tiles in the automotive industry enhance motor performance and durability, especiall...

Read MoreHousehold appliances like washing machines, refrigerators, and air conditioners rely on efficient mo...

Read MoreIn the medical industry, especially for high-precision devices such as MRI machines, motor porcelain...

Read MoreMotors in treadmills and other fitness equipment need to operate for extended periods without overhe...

Read MoreIn industrial and household cleaning equipment such as pressure washers and floor cleaners, motor po...

Read MoreMotor porcelain tiles play a crucial role in various industrial applications, such as fans, pumps, a...

Read MoreIn the aviation and marine fields, motor tiles need to withstand higher environmental pressures and ...

Read MoreIn garbage processing and other environmental equipment, motor porcelain tiles ensure that motors re...

Read MoreProvide you with the latest enterprise and industry news

Treadmill magnetic tiles are integrated into motor assemblies to influence torque distribution and belt motion stability. These tiles, typically made from ferrite or neodymium materials, generate magnetic fields that support even torque patterns across varying speeds. Laboratory measurements indicate that treadmill belts with magnetic tiles can exhibit approximately 15–20% lower vibration amplitude, while motors complete roughly 10–15% more operational cycles than similar designs without magnetic tiles. These characteristics are important in both home and commercial gym environments, where consistent performance is critical. Magnetic tiles in treadmill motors contribute to stable belt movement across different workout intensities. Tests show that belt speed variation can remain around 5% under standard load conditions, which provides predictable pacing for walking, jogging, and running sessions. In addition, the reduced vibration translates into smoother operation, which aligns with user observations of quieter and more consistent motion. Noise measurements suggest a reduction of 3–5 dB in treadmill motor assemblies containing magnetic tiles, supporting a more comfortable exercise experience in shared living spaces or fitness centers. Ferrite-based magnetic tiles are valued for their thermal stability, maintaining magnetic behavior at temperatures up to 80°C. This property ensures predictable performance even under continuous use, such as during prolonged training sessions or high-frequency commercial operations. Motor assemblies with magnetic tiles also demonstrate lower mechanical stress over repeated cycles, which can contribute to longer operational life for treadmill belts and drive systems. In addition to motor stability, magnetic tiles are applied in certain resistance systems for fitness equipment. By varying the magnetic field strength, these systems allow changes in resistance without mechanical wear, illustrating broader applications of magnetic technology in exercise design. Prototypes tested under repeated cycles show consistent torque behavior and belt tension, suggesting that magnetic tiles help maintain predictable operation over thousands of workout sessions. Observations in multiple treadmill models indicate that tiles retain magnetic properties even after extended daily use, which supports predictable motor behavior over time. When considering treadmill magnetic tiles, practical factors include proper alignment during assembly, material selection, and the interaction of magnets with other treadmill components. Correct placement ensures balanced torque distribution and reliable belt motion. Manufacturers often adjust tile spacing and magnetic strength to match motor specifications and target operational conditions, supporting consistent performance across varying user weights and speeds. Users also report that treadmill belts maintain uniform contact with rollers and frames, which contributes to overall mechanical stability. FAQs What do treadmill magnetic tiles do? They influence torque patterns and support steady belt motion in treadmills. Are magnetic tiles durable? Ferrite and neodymium tiles maintain consistent behavior under elevated temperatures and repeated cycles. Do magnetic tiles affect treadmill noise? Measurements indicate lower operational noise and smoother motion in motors equipped with magnetic tiles. Do magnetic tiles influence exercise performance? Consistent belt motion supports predictable pacing and user experience. Are magnetic tiles expensive? Costs vary depending on material quality and treadmill design specifications. Treadmill magnetic tiles are increasingly incorporated into fitness equipment, providing stability, predictable torque distribution, and consistent belt operation. By understanding their role in treadmill motors, designers and users can ensure reliable performance across a variety of workout conditions, contributing to smoother and more durable exercise equipment. Observations also show that motor assemblies maintain these characteristics even under varied usage patterns, reflecting the tiles’ contribution to mechanical reliability over time.

Household appliances magnetic tiles are integrated into motors in devices such as washing machines, vacuum cleaners, and refrigerators. These magnetic components are arranged to generate magnetic fields that influence torque distribution and motor behavior, supporting stable rotational speed and predictable performance. Appliances equipped with motors containing magnetic tiles can operate with roughly 15–25% lower variation in energy draw under typical household conditions, which is relevant for monitoring electricity use over time. The widespread adoption of neodymium magnets has contributed to more compact motor designs. NdFeB materials allow motor assemblies to occupy nearly 50% less volume while maintaining comparable magnetic behavior. In variable-speed washing machines and air conditioners, magnetic tiles support consistent motor performance across different operational settings. Measurements of vibration amplitude indicate that motors with magnetic tiles can produce approximately 20–30% lower oscillations compared with conventional assemblies, contributing to quieter operation and reduced mechanical wear. Refrigerator compressors, vacuum motors, and small kitchen appliances also benefit from magnetic tiles. Laboratory tests show that motors with magnetic tiles maintain operational stability over 15–20% more cycles than comparable devices without these components. This stability ensures predictable rotational behavior, which aligns with consumer expectations for reliable appliance performance. In vacuum cleaners, for example, magnetic tile-equipped motors exhibit consistent suction levels across multiple cleaning cycles. Magnetic tiles also support energy efficiency objectives. Appliances with these motors demonstrate more uniform electrical draw during operation, which can correlate with modest reductions in energy consumption in homes with multiple high-use appliances. Noise measurements indicate up to 3–5 dB lower sound levels in smaller devices, providing quieter operation and improved user experience in shared living spaces. Magnetic tiles are manufactured in a variety of shapes, sizes, and magnetic strengths, giving designers flexibility when assembling motors. Proper placement and orientation influence torque behavior under varying loads, which is relevant for both consumer-grade and commercial devices. For high-use appliances, this design flexibility allows manufacturers to meet operational consistency and regulatory standards, particularly in regions with specific energy efficiency requirements. Observations indicate that homes using appliances with magnetic tiles can experience slightly lower cumulative energy usage, reflecting more stable performance patterns. Additional practical considerations include temperature stability and material durability. Magnetic tiles maintain consistent magnetic behavior within typical operating ranges, which is important for appliances exposed to varying temperatures during cycles such as washing, refrigeration, or drying. The integration of these components is compatible with standard assembly processes and does not introduce safety risks, as the magnets are enclosed within motor housings. FAQs Are magnets common in household appliances? Yes, magnets are integrated into many motor assemblies across a wide range of devices. Do magnetic tiles influence operational behavior? Evidence shows that magnetic tiles affect torque distribution and rotational characteristics under standard use. Do magnetic tiles affect appliance durability? Motors with magnetic tiles maintain consistent operation over more cycles, supporting reliable performance. Are magnetic tiles costly? Costs vary depending on material quality and motor design specifications. Do magnets present safety concerns? Enclosed magnets pose no risk during normal appliance operation. Household appliances magnetic tiles contribute to consistent motor behavior, supporting stable operation, predictable performance, and quieter use across everyday devices. By integrating magnetic tiles, manufacturers can deliver reliable and long-lasting appliances that meet consumer expectations for performance and efficiency.

Customized magnetism shoes offer innovative options for both occupational and casual footwear. By integrating magnetic components, these shoes provide new approaches to fastening, traction, and user interaction. This guide will help readers understand how magnetism is applied in footwear, key considerations when using these shoes, and practical examples from industry and consumer use. Understanding Magnetic Fastening Systems One of the main applications of customized magnetism shoes is magnetic fastening. Some shoes replace traditional laces with magnetic closures that generate attachment forces of approximately 15–20 pounds. These systems allow wearers to secure footwear without tying knots, maintaining consistent positioning during everyday activity. For casual or athletic use, magnetic closures can handle repeated attachment and release across thousands of cycles, supporting long-term functionality. When selecting footwear with magnetic fastening, consider the alignment of the magnets and the ease of engagement and release, as these factors influence comfort and usability. Industrial Applications and Traction Features Magnetic footwear is increasingly adopted in industrial settings where metal surfaces are common. Magnets embedded in shoe soles interact with steel platforms, scaffolding, or inclined surfaces, providing additional stability. In some designs, pulling forces can reach around 150 pounds per shoe, helping workers maintain secure footing on sloped or elevated metal surfaces. Field observations indicate that the use of magnetic shoes in construction and manufacturing has grown by approximately 10% per year, highlighting their integration into occupational safety programs. When evaluating industrial magnetic shoes, check the distribution and strength of magnetic elements to ensure reliable performance under work conditions. Experimental and Consumer-Oriented Designs Beyond industrial applications, magnetic elements in footwear are explored in experimental and consumer-focused designs. Some prototypes use magnetic repulsion to create unique walking or movement experiences. While these designs are often showcased in exhibitions or design competitions, they illustrate how magnetic technology can be creatively applied in footwear engineering. For consumers, magnetic shoes with novel features may provide convenience in daily wear, such as faster fastening or adjustable fit, without requiring significant changes to standard shoe design. Practical Considerations for Use When using customized magnetism shoes, several factors influence performance and user satisfaction: Weight and balance: Magnetic components add some mass to footwear. Proper weight distribution supports stability and comfort during walking or standing. Environmental interaction: Exposure to metal surfaces, moisture, or bad temperatures can influence magnetic behavior. Users should consider the work or activity environment when selecting shoes. Magnet durability: Magnetic elements maintain attachment forces across repeated cycles of fastening. Testing under varying temperatures or humidity shows that functional performance remains consistent over hundreds of cycles. By paying attention to these aspects, users can select magnetic shoes that provide practical benefits for occupational or everyday use. FAQs What are customized magnetism shoes? Footwear or accessories that integrate magnets for fastening or traction purposes. Are magnetic closures durable? Closures retain functional attachment across repeated cycles of use. Can magnets influence traction? Certain designs provide stability on metal surfaces, such as steel platforms or scaffolding. How should magnetic shoes be maintained? Keep shoes clean and dry, avoid strong interference from electronic devices, and inspect magnetic components periodically for alignment or wear. Who can benefit from customized magnetism shoes? They can be used in construction, manufacturing, occupational safety, or casual settings where convenience and stability are priorities. Customized magnetism shoes provide practical options for occupational and daily footwear, combining functionality with innovative design. By understanding how magnetic components work, considering environmental factors, and choosing appropriate models, users can integrate magnetic footwear into various settings with consistent performance and convenience.

Motor magnetic tiles are increasingly integrated into electric motors used in industrial equipment, household appliances, and automotive systems. These tile-shaped magnetic elements, usually made from ferrite or neodymium, create magnetic fields that influence torque distribution and motor behavior. In automotive electric motors, the inclusion of magnetic tiles has been associated with about 12% lower energy loss during standard driving cycles. Electric vehicle (EV) traction motors are among the common applications. Magnetic tiles are arranged around rotors or stators to direct magnetic flux in controlled paths. Observations suggest that motors with well-placed magnetic tiles can maintain approximately 8% higher efficiency under similar conditions. Torque output remains relatively uniform across speed ranges, and vibration measurements show lower amplitude in motor assemblies equipped with magnetic tiles. Household appliances such as washing machines, refrigerators, and air conditioners also incorporate magnetic tiles in their motors. These magnets are linked to more consistent rotational speed and reduced mechanical oscillations. Data from operational tests indicate motors with magnetic tiles can function reliably for 20–30% more operating hours under normal household usage. NdFeB materials allow for compact motor construction while maintaining magnetic performance in small-scale devices. Industrial automation and cleaning machinery frequently include magnetic tiles to maintain predictable motor behavior in continuous operation or under variable loads. For example, floor cleaning robots with motors containing magnetic tiles demonstrated stable movement patterns across repeated cycles in laboratory tests. Motors in medical devices use magnetic tiles to maintain controlled torque across repeated operating cycles, supporting predictable mechanical behavior for sensitive applications. Magnetic tiles are available in various sizes, thicknesses, and magnetic strengths, providing designers with flexibility in motor construction. The ability to customize tile placement allows for optimization of field distribution, contributing to predictable rotational behavior. Observations show that assemblies with magnetic tiles also tend to have lower acoustic emission, which can be beneficial in residential or laboratory settings. The use of magnetic tiles is also reflected in industry reports on motor reliability. Manufacturers note that integrating these components can cause more stable operation under fluctuating voltage conditions and reduced mechanical wear over extended operational periods. In EV traction motors, repeated acceleration and deceleration cycles indicate that magnetic tiles maintain consistent torque behavior compared with motors without these components. Industrial equipment with magnetic tile motors also operates with more predictable current draw, which can support energy management strategies in larger facilities. Motor magnetic tiles continue to be an important element across applications, supporting design flexibility, predictable torque behavior, and consistent operation in motors used in vehicles, appliances, and industrial equipment. FAQs What are motor magnetic tiles used for? They create magnetic fields in motors, influencing torque and rotational characteristics. Do magnetic tiles affect motor reliability? Their inclusion is associated with longer operational hours and more stable torque patterns. Can magnetic tiles be customized? They can be produced in different sizes, thicknesses, and magnetic properties to match motor requirements. Do magnetic tiles affect energy patterns? Data indicate they influence energy behavior in motors under typical operating conditions. Is special handling required during installation? Proper alignment and positioning are important for expected motor behavior. Motor magnetic tiles remain a functional component in modern motor design, contributing to predictable behavior and reliable operation in a range of applications.

Robot lawn mowers are becoming a popular way for homeowners to maintain their lawns with minimal effort. A key accessory for these machines is lawn mower magnetic tiles, which define the mowing area and prevent the mower from entering unwanted spaces. These tiles guide the mower accurately, protect plants, and make lawn maintenance faster and more reliable. Lawn mower magnetic tiles are installed along lawn edges, around trees, flower beds, and other obstacles. They emit a magnetic signal that the mower detects, keeping it within the designated area. Homeowners report that using these tiles reduces accidental collisions by more than 70% and improves mowing coverage by around 80%. This means the mower can work more efficiently without missing spots or damaging landscaping. Installing magnetic tiles is simple but requires careful planning. Most tiles come as flexible strips or modular panels that can form a continuous loop. Placing the tiles slightly inside the lawn boundary ensures the mower detects them properly. If the tiles are too far outside the boundary, the mower may skip areas or make extra passes, wasting battery and time. Planning the layout before installation helps the mower follow a smooth and consistent path. Magnetic tiles are compatible with many robot mowers, but small differences in sensor sensitivity can exist between models. Correct placement ensures the mower performs consistently. Once installed, the tiles need little adjustment unless the landscape changes. Their durability also means they can last for many years with minimal maintenance, making them a practical investment. Using magnetic tiles also saves energy. By keeping the mower on a defined path, unnecessary movement is reduced, which lowers battery use. On average, mowers with magnetic tiles use about 15% less energy per mowing cycle. This allows them to run longer on a single charge and reduces the frequency of recharging. It also ensures the mower can complete the lawn in fewer passes, saving time for the homeowner. Durability is another advantage. Magnetic tiles are designed to withstand outdoor conditions, including rain, sun, and soil moisture. Once properly installed, they can last 8 to 10 years, making them a low-maintenance solution that improves both efficiency and reliability. FAQ Q1: Can magnetic tiles be buried underground? A1: Yes, they can be buried a few centimeters below the surface to protect them and keep the lawn tidy. Q2: How long do magnetic tiles last? A2: High-quality tiles usually last 8 to 10 years depending on weather and soil conditions. Q3: Are magnetic tiles compatible with all robot mowers? A3: Most are compatible, but checking the installation guide ensures proper detection. Q4: Can I expand the mowing area later? A4: Yes, additional tiles can be added, but they should form a continuous loop for accurate detection. In conclusion, lawn mower magnetic tiles are a practical and essential accessory for achieving effective and efficient robot lawn care. They help the mower navigate more accurately, reduce unnecessary energy consumption, and prevent collisions with plants and obstacles. Built to last for many years, these tiles provide a low-maintenance and reliable solution. By clearly defining the mowing area, they allow the mower to work consistently and smoothly, saving time and effort for homeowners while keeping lawns neat, healthy, and well-maintained throughout the seasons.

A modern magnetic tiles factory plays an important role in the supply chain of electric motors, household appliances, and industrial equipment. Unlike consumer products, industrial magnetic tiles—often referred to as magnetic segments or ferrite tiles—are core functional components. Their performance directly affects motor efficiency, energy consumption, and operational stability. Three areas stand out in current factory operations: material consistency, precision manufacturing, and application-driven customization. Material Control and Performance Stability Industrial magnetic tiles are commonly produced from ferrite or rare-earth magnetic materials. These materials require strict formulation control during powder preparation, pressing, and sintering. Small deviations in composition or density can influence magnetic flux density, coercivity, and temperature resistance. Industry testing data shows that magnetic performance deviation beyond five percent may reduce motor efficiency by more than three percent in certain applications. For this reason, factories invest heavily in raw material inspection and batch traceability. Incoming powders undergo chemical analysis and particle size evaluation before entering production. Sintering remains one of the critical stages. Kiln temperature stability and atmosphere control determine final magnetic strength and structural integrity. Many magnetic tiles factories operate continuous kilns equipped with real-time monitoring systems to maintain uniform thermal conditions throughout each production cycle. Precision Manufacturing and Dimensional Accuracy Dimensional accuracy is another central topic in factory discussions. Industrial magnetic tiles must match strict tolerances to fit motor rotors or stators. Even minor dimensional variation can cause vibration, noise, or assembly failure. Factories rely on high-pressure pressing molds and CNC grinding to achieve consistent geometry. Automated inspection systems measure thickness, arc angle, and surface flatness at multiple points. Statistical process control data from established manufacturers indicates that dimensional tolerance is often controlled within ±0.02 mm for standard motor applications. Surface finishing also matters. Smooth surfaces improve bonding performance during assembly, especially when magnetic tiles are fixed using adhesives or resin systems. As a result, polishing and surface treatment steps receive increasing attention during final inspection. Customization for Industrial and Appliance Use Customization demand continues to shape the structure of a magnetic tiles factory. Manufacturers of electric motors, compressors, fans, and generators often require specific arc shapes, magnetization directions, or performance grades. Industrial procurement data suggests that customized magnetic tiles account for over half of total factory output in export-oriented facilities. Instead of producing large volumes of identical parts, factories manage multiple small-to-medium batch orders tailored to specific equipment models. Engineering teams use magnetic simulation software to adjust magnet geometry and performance parameters before tooling begins. This reduces development cycles and limits trial-and-error costs. Typical time from design confirmation to pilot production ranges from four to eight weeks, depending on complexity. Factory Operations and Compliance Requirements Daily operations inside a magnetic tiles factory combine automation and skilled labor. Pressing, sintering, and grinding processes are largely automated, while magnetization, inspection, and packaging involve trained technicians. Final inspection includes magnetic performance testing, dimensional checks, and visual examination. Compliance has become a routine part of factory management. Many buyers request documentation related to ISO 9001 systems, material data sheets, and performance test reports. Traceability records help link finished products to specific production batches, supporting long-term supply stability. FAQ What are industrial magnetic tiles mainly used for? They are widely used in electric motors, household appliances, compressors, fans, and industrial machinery. Which materials are common in magnetic tile production? Ferrite materials are common, while some applications require rare-earth magnetic compounds. How do factories ensure magnetic performance consistency? Through strict raw material control, controlled sintering processes, and batch-level magnetic testing. Can magnetic tiles be customized for specific equipment? Yes. Shape, size, magnetization direction, and performance grade are commonly customized.

Car magnetic tiles are widely used components in electric motors found in automobiles and household appliances. These tiles, typically manufactured as arc-shaped or segmented permanent magnets, are designed to generate stable magnetic fields within motor systems. Their structure allows engineers to control magnetic flux distribution, which plays an important role in motor efficiency, torque stability, and operational reliability. In automotive applications, magnetic tiles are commonly installed in traction motors, auxiliary drive motors, and electric pumps. Electric and hybrid vehicles rely on multiple motor systems to support propulsion, steering assistance, cooling, and braking functions. Each of these systems requires consistent magnetic performance to maintain smooth operation under varying loads and speeds. Magnetic tiles help meet these requirements by offering predictable magnetic behavior and mechanical compatibility with rotor assemblies. A typical electric vehicle motor may contain dozens of magnetic tiles arranged in a circular configuration. This segmented design allows heat dissipation to be managed more effectively compared with single-piece magnets. It also reduces internal stress during high-speed rotation, which contributes to longer motor service life. As a result, magnetic tiles are often selected for automotive motors that operate continuously or under demanding driving conditions. Household appliances represent another major application area for magnetic tiles. Motors used in washing machines, refrigerators, air conditioners, and ventilation systems depend on stable magnetic fields to achieve consistent speed control and energy usage. In these appliances, magnetic tiles are valued for their resistance to temperature variation and their ability to maintain magnetic strength over long operating cycles. In washing machines, for example, motor performance directly affects drum speed accuracy and vibration control. Magnetic tiles help ensure that motors respond precisely to control signals, supporting both low-speed washing cycles and higher-speed spin operations. In air conditioning systems, magnetic tiles contribute to the steady operation of compressors and fans, which is essential for maintaining indoor comfort and reducing mechanical wear. Beyond end products, magnetic tiles are also used in industrial environments related to automotive and appliance manufacturing. They can be found in motor testing equipment, automated assembly lines, and material handling systems. In these settings, magnetic tiles may serve both as functional motor components and as magnetic holding elements that assist with positioning metal parts during production. Material selection is a key consideration in magnetic tile design. Ferrite magnetic tiles are commonly used due to their cost stability and corrosion resistance, while higher-performance materials may be selected for compact motors requiring stronger magnetic fields. Surface treatments and coatings are often applied to improve durability and protect against moisture or chemical exposure. As automotive systems continue to rely on electric motors, car magnetic tiles remain a foundational component supporting efficiency, reliability, and mechanical precision across a wide range of applications. FAQ What are car magnetic tiles? Car magnetic tiles are segmented permanent magnets used inside motors for vehicles and related systems. They help generate controlled magnetic fields for motor operation. Why are magnetic tiles used instead of single magnets? Segmented tiles allow better heat management, reduced mechanical stress, and more flexible magnetic design within motor assemblies. Are magnetic tiles used only in vehicles? No. They are also widely used in household appliances such as washing machines, air conditioners, and refrigerators. What materials are commonly used for magnetic tiles? Magnetic tiles are commonly made from ferrite materials, with other magnetic materials used when higher magnetic strength is required. Do magnetic tiles affect motor lifespan? Yes. Properly designed and installed magnetic tiles help reduce vibration and thermal stress, which can support longer motor operating life.

High Performance Neodymium-iron-boron magnets, commonly called High Performance NdFeB magnets, are now a regular part of many industrial products. One reason they are chosen so often is that they can create useful magnetic fields without taking up much space. Engineers use them in electric vehicle motors, wind turbine generators, and different kinds of factory machines. Because working conditions vary from one product to another, the magnets are adjusted during design and production to match those conditions. In automotive work, especially for electric and hybrid cars, NdFeB magnets form a central part of the traction motors. These motors need magnets that give a reasonable level of energy density so that power can be delivered from a limited volume. Cars run at different speeds and experience changing temperatures, from cold starts to heavy loads on highways. The magnets therefore have to keep their magnetic strength through these normal operating changes. A method that is often used is grain boundary diffusion. Small amounts of dysprosium or terbium are added along the boundaries between crystal grains inside the magnet. This step raises the coercivity level, which means the magnet becomes more resistant to losing its field, and it does so without making the piece noticeably larger or heavier. Temperature behaviour is another area that receives attention in car-related designs. Vehicles regularly go through heating and cooling as drivers move through traffic or park in different weather. Development efforts look at ways to change the alloy composition and control the internal grain structure. Such changes allow the magnets to handle many thermal cycles without losing performance. Hot-deformed NdFeB magnets are one outcome of this work. They show better resistance to temperature effects and higher coercivity, and they achieve this while using smaller quantities of certain earth materials that are harder to obtain. When it comes to wind turbines and industrial machinery, the main requirements centre on steady operation over long periods. Wind generators are expected to turn for decades with little downtime, often in locations far from repair facilities. Factory equipment such as pumps, fans, and conveyor drives also runs continuously. Both types of systems expose the magnets to shifting temperatures, mechanical vibration, and sometimes damp air. The magnets must therefore avoid demagnetisation and deliver consistent output year after year. Hot deformation is again helpful here because it aligns the crystal grains in a way that adds mechanical strength and improves thermal properties. Careful control of the microstructure also contributes by producing a more even internal layout that copes better with daily stresses. One drawback of NdFeB magnets is that they can corrode if moisture reaches the material. The iron in the alloy reacts with water and oxygen, forming rust over time. To prevent this, manufacturers add protective layers during production. Nickel plating is a frequent choice, sometimes combined with copper or other intermediate coatings. Epoxy resin coatings are also widely applied, particularly when parts will be used outdoors. These surface treatments act as barriers and help the magnets last longer in real conditions. Careful storage and correct installation further reduce the risk of early damage. Overall, High Performance NdFeB magnets remain an important element in today's automotive, renewable energy, and general industrial equipment. Vehicle motors benefit from their energy density and ability to work across temperature ranges. Wind and heavy machinery designs rely on their long-term stability and resistance to daily wear. Continued work on diffusion methods, deformation processes, microstructure control, and surface protection keeps improving what these magnets can do.

In recent years, permanent magnetic ferrite materials have drawn increasing attention in sectors using electric motors, from cleaning machines to small industrial devices. Their combination of cost‑effectiveness, thermal stability, and magnetic retention makes them a frequent choice when designing motors requiring durability and long service life. Why Engineers Choose Ferrite Magnets Permanent magnetic ferrite magnets offer several advantages that meet the demands of industrial motors: Thermal tolerance: Ferrite materials hold magnetic properties even under elevated temperatures common in continuous operation, reducing risk of demagnetization. Corrosion resistance: Properly coated ferrite magnets resist moisture and chemical exposure, ensuring longevity even in damp or harsh environments (e.g., cleaning machines or industrial floor scrubbers). Cost and manufacturability: Compared with high‑end rare‑earth magnets, ferrite provides a balance of magnetic strength and affordability, useful when many magnet segments are needed or when replacements may be frequent. Sufficient magnetic strength for many applications: For motors designed for moderate torque and continuous duty rather than maximal power density, ferrite magnets deliver reliable performance with stable flux output. These characteristics have led to ferrite magnets being widely specified in cleaning equipment, exhaust fans, small‑scale motors, and commercial cleaning robots. Practical Performance Records Users and maintenance teams report several performance insights based on real-world use of ferrite‑magnet motors: Motors operating 6–9 hours per day in commercial cleaning devices show consistent rotational speed and torque stability over months of service. Instances of demagnetization under heavy thermal stress when magnets are used with appropriate coatings and are assembled under precision control. Devices with ferrite magnets tend to exhibit lower maintenance frequency compared with older motor designs — fewer bearing failures and less magnet replacement over time. For cleaning machines or floor scrubbers, the smoother torque output results in more uniform brush pressure, more consistent cleaning quality over extended runs. Such feedback has encouraged more facility operators to specify ferrite‑magnet motors in their procurement criteria, valuing long‑term reliability and manageable maintenance over maximal power output. Design and Manufacturing Considerations When integrating permanent magnetic ferrite magnets into motor designs, manufacturers discuss several key parameters: Magnet geometry and placement — the size, shape, and orientation of each ferrite block or segment must align precisely to ensure balanced magnetic flux and avoid uneven rotor behavior. Coating and bonding — magnets used in machines exposed to dust, water, or cleaning chemicals require protective coatings and secure bonding to prevent corrosion or detachment. Thermal management — although ferrite is more thermally stable than many alternatives, designers still account for heat generation under heavy load, using venting, cooling, or heat-resistant housing materials. Spare part strategy — because ferrite is affordable and segmented magnets are easier to replace, many manufacturers maintain spare magnet kits, simplifying maintenance and reducing downtime. These considerations help ensure that ferrite‑magnet motors remain dependable in demanding operational contexts, such as warehouses, hospitals, factories, or public facilities. Use Cases Several application areas currently rely heavily on ferrite‑magnet motors: Commercial floor cleaning machines — where consistent brush or roller motion and long service intervals are valuable. Ventilation and exhaust equipment — motors run for hours daily and benefit from magnetic stability and corrosion resistance. Small industrial devices and pumps — where cost and durability outweigh the need for torque density. Autonomous cleaning robots or compact machines — where weight, cost, and maintenance simplicity are key. In summary, permanent magnetic ferrite remains a widely used and practical choice for motors in cleaning machines, ventilation units, and small industrial equipment.

Cleaning machine magnetic tiles are critical components for motors used in industrial floor scrubbers, commercial sweepers, and automatic cleaning machines. Proper selection and maintenance of these tiles can directly affect motor efficiency, operational stability, and overall machine reliability. Understanding the materials, geometry, and installation methods is essential for manufacturers, maintenance teams, and procurement specialists seeking long-term operational consistency. Function and Role in Cleaning Machines Magnetic tiles are segmented, arc-shaped magnets mounted on the rotor of a cleaning machine motor. They provide a stable and uniform magnetic field that ensures: Consistent torque output under varying load conditions Reduced motor vibration and operational noise Smooth rotation, particularly in machines operating for multiple hours continuously Efficient energy usage, minimizing current spikes and overheating In industrial and commercial cleaning machines, such as floor scrubbers and autonomous cleaning robots, magnetic tiles play a central role in maintaining consistent brush and roller motion, which directly impacts cleaning performance and surface protection. Material Considerations Choosing the correct material is essential for performance: Ferrite Tiles: Offer thermal stability, resistance to demagnetization, and cost efficiency. They maintain performance in high-duty cycles, such as cleaning large warehouses or hospitals. Ceramic Tiles: Provide higher dimensional precision and uniform magnetic alignment, suitable for compact, high-speed motor designs. Protective coatings: These safeguard the tiles from moisture, cleaning solutions, and mechanical wear. Coated tiles resist corrosion and extend service life. Material selection should also consider the operating environment. Facilities with high humidity, chemical exposure, or continuous operation may require tiles with enhanced thermal tolerance or specialized coatings. Tile Geometry and Installation Proper sizing and alignment of magnetic tiles are crucial: Arc length and thickness: Must match the rotor design to prevent uneven magnetic pull and vibration. Magnetization direction: Correct orientation ensures uniform flux distribution and stable rotational speed. Segmented design: Allows replacement of individual tiles without disassembling the entire rotor, reducing maintenance downtime and service costs. Industrial operators note that precise alignment prevents torque fluctuation, minimizes energy loss, and improves operational stability, particularly in machines running on variable floor surfaces. Maintenance Practices Routine inspection and maintenance of magnetic tiles can prevent operational issues: Check for cracks, chips, or misalignment regularly. Inspect magnetic strength periodically to ensure consistent torque. Replace individual segments as needed, which avoids full rotor replacement. Well-maintained magnetic tiles help reduce motor wear, extend component life, and maintain the efficiency of cleaning operations over time. Performance Observations Data from industrial use and field feedback suggest: Motors with ferrite tiles operate continuously for 5–8 hours per day without significant performance loss. Machines using segmented magnetic tiles show lower vibration and smoother brush or belt movement. Torque output remains stable during sudden changes in load, such as inclines or uneven floors. Energy consumption is more predictable, reducing overall operational costs in large facilities. Such characteristics are particularly valuable for cleaning machines deployed in high-traffic areas like warehouses, hospitals, airports, and logistics centers. Procurement and Selection Checklist When sourcing cleaning machine magnetic tiles, consider: Compatibility with the motor rotor dimensions Material grade and thermal tolerance Tile arc length, thickness, and magnetization direction Availability of spare tiles for maintenance Protective coatings and bonding methods for durability Suppliers often provide technical drawings and sample tiles for testing to ensure the selected components meet operational requirements. Customization is common to fit specific motor designs or application needs. Conclusion Cleaning machine magnetic tiles are essential for maintaining reliable motor performance, stable torque, and consistent cleaning efficiency in industrial and commercial machines. Correct material selection, precise installation, and regular maintenance ensure long-term operational stability and minimize downtime. For manufacturers and facility managers, understanding the technical specifications and replacement strategy is key to maintaining machine performance. Suppliers can provide detailed specifications, sample tiles, and technical support to meet diverse operational needs.