Description:

Introduction:

The Cleaning Machine Magnetic Tiles involves the production and provision of high-quality magnetic components tailored for various applications. These Cleaning Machine Magnetic Tiles play pivotal roles in numerous industries, including automotive, electronics, and renewable energy.

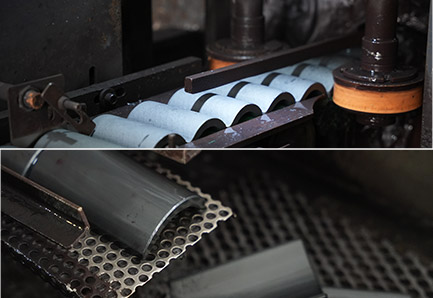

Manufacturing Process:

The Cleaning Machine Magnetic Tiles are meticulously crafted through advanced manufacturing techniques. The process begins with the formulation of raw materials, typically neodymium iron boron (NdFeB) powder, along with additives to enhance magnet performance. The materials are then compacted using a dry pressing method under controlled conditions, ensuring precise shaping and density. Subsequently, the compacted segments undergo sintering at high temperatures, followed by machining to achieve the desired dimensions and surface finish.

Properties:

These Cleaning Machine Magnetic Tiles boast nice magnetic properties attributed to their isotropic nature. They exhibit great magnetic characteristics in all directions, enabling versatile applications. With high coercivity and remanence, these Cleaning Machine Magnetic Tiles deliver good magnetic strength and stability. Their special shapes allow for efficient flux concentration and distribution, improving performance in diverse environments. Furthermore, they exhibit nice resistance to demagnetization, ensuring a prolonged operational lifespan.

Applications:

The versatility of the Cleaning Machine Magnetic Tiles renders them indispensable across various industries. In the automotive sector, they find applications in electric vehicle drivetrains, power steering systems, and hybrid propulsion systems, contributing to enhanced efficiency and performance. In the electronics industry, these magnets are utilized in sensors, actuators, and loudspeakers, facilitating precise control and signal processing. Additionally, they play crucial roles in renewable energy technologies such as wind turbines and electric generators, promoting sustainable power generation.

Moreover, the continuous advancements in material science and manufacturing technologies contribute to the ongoing evolution of the Cleaning Machine Magnetic Tiles. Research and development efforts focus on enhancing magnet performance, durability, and cost-effectiveness to meet the ever-growing demands of modern applications. Collaborations between industry important and academic institutions drive innovation, nice to the discovery of novel materials and fabrication techniques. As a result, the future holds promising prospects for further improvements in magnet design, enabling even more efficient and versatile solutions for tomorrow's technological challenges. By staying at the important area of these developments, manufacturers and users alike can harness the full potential of the Cleaning Machine Magnetic Tiles to drive progress and innovation across a wide range of industries.

Benefits:

The utilization of the Cleaning Machine Magnetic Tiles offers numerous benefits to end-users. Their high magnetic strength enables compact and lightweight designs without compromising performance. Moreover, their nice stability ensures reliable operation under demanding conditions, reducing downtime and maintenance costs. The tailored shapes of these magnets optimize flux density and distribution, enhancing overall system efficiency. Additionally, their compatibility with various manufacturing processes facilitates seamless integration into existing applications, promoting innovation and competitiveness.

Conclusion:

In conclusion, the Cleaning Machine Magnetic Tiles represent good magnetic solutions with good applications across diverse industries. Their advanced manufacturing process, coupled with good properties and tailored shapes, positions them as important components in modern technologies. By harnessing the capabilities of these magnets, businesses can achieve enhanced performance, efficiency, and sustainability in their products and systems.

+86 18768188974

+86 18768188974