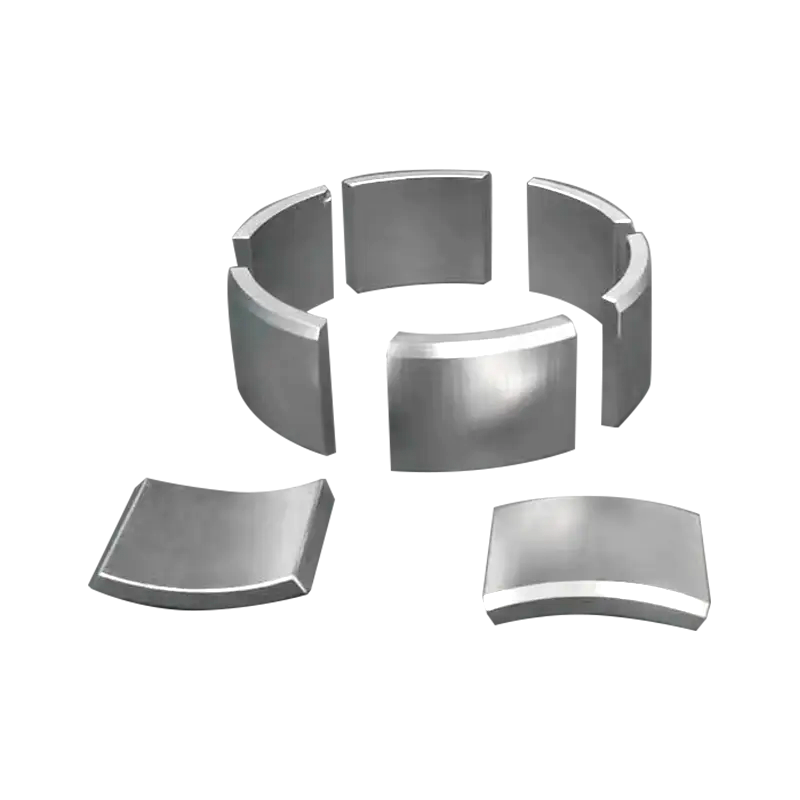

Dong Yang TianQi Magnetic Segment Co.,Ltd.(formerly Shuangyang Magnet Tile) is a professional enterprise specializing in the production of motor magnet tiles

Search by posts

Categories

Popular products

Contact Us

Industry News

By Admin

By Admin

Cleaning Machine Ferrite Magnetic Tiles: Revolutionizing Industrial Hygiene

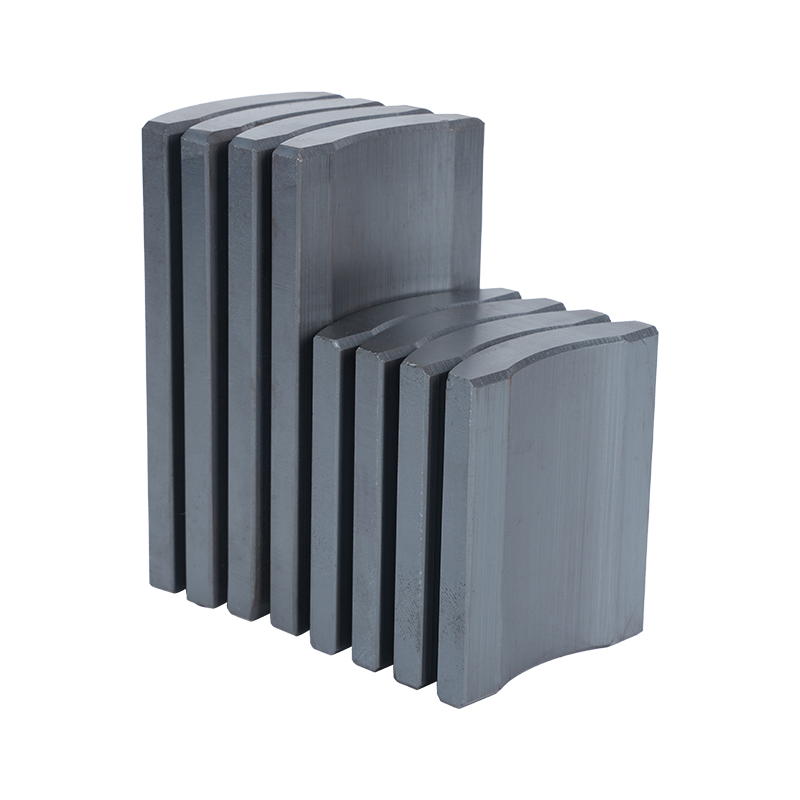

In the quest for cleaner, more efficient industrial processes, Cleaning Machine Ferrite Magnetic Tiles have emerged as a powerful solution. These innovative tiles, designed to be integrated into various cleaning machines, are transforming the way we approach hygiene and maintenance in industries ranging from food processing to automotive manufacturing. With their ability to attract and hold fine metal particles, Cleaning Machine Ferrite Magnetic Tiles are setting new standards for cleanliness and safety.

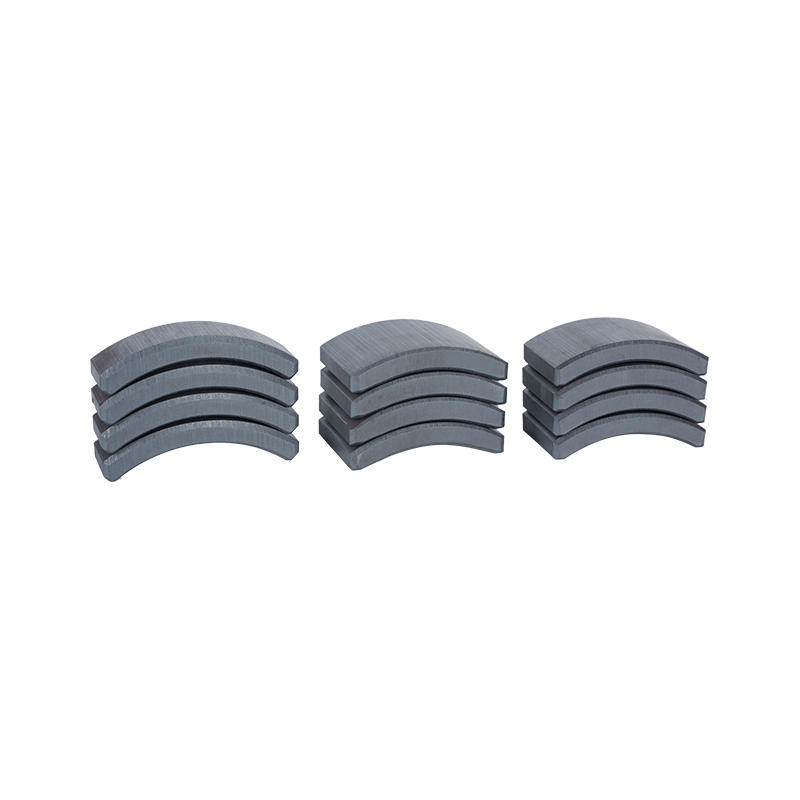

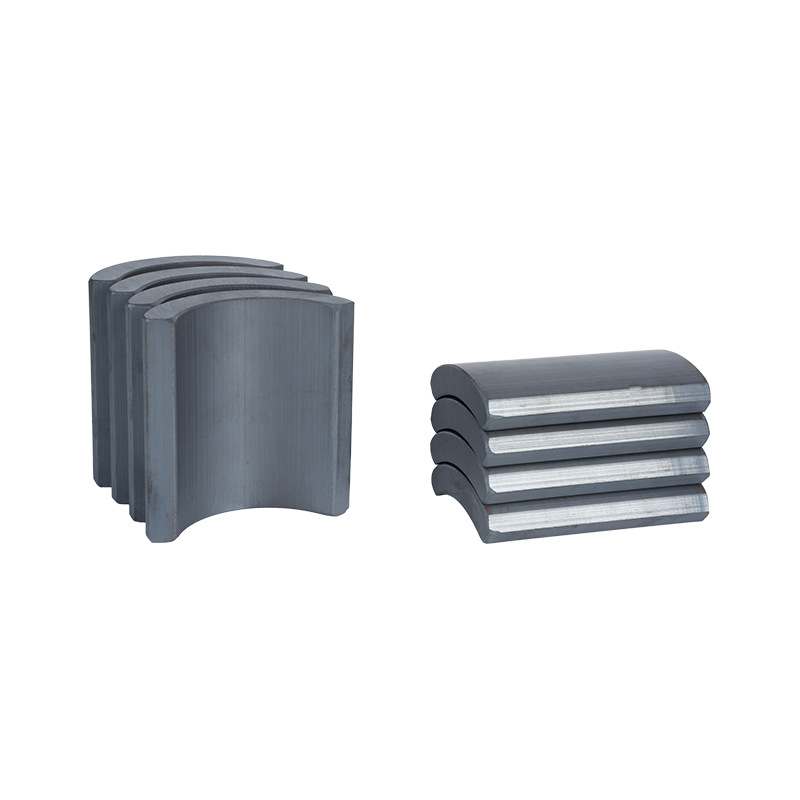

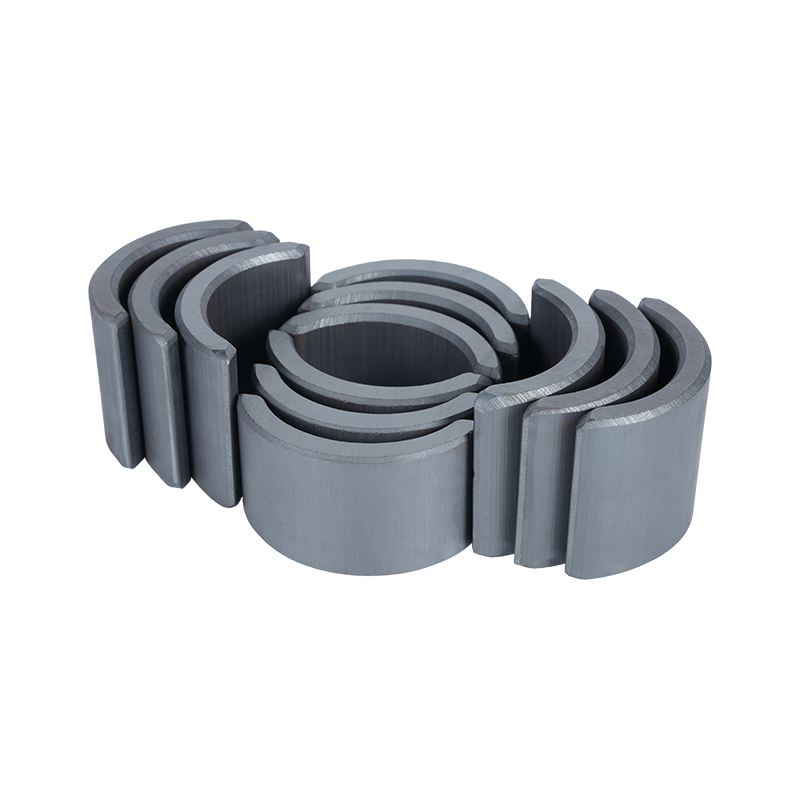

Ferrite, a type of ceramic material known for its magnetic properties, forms the backbone of these magnetic tiles. The unique composition of Cleaning Machine Ferrite Magnetic Tiles allows them to generate a strong, consistent magnetic field that is capable of attracting even the smallest metal fragments. This ensures that surfaces are not only cleaned but also safeguarded against potential contamination from metal particles.

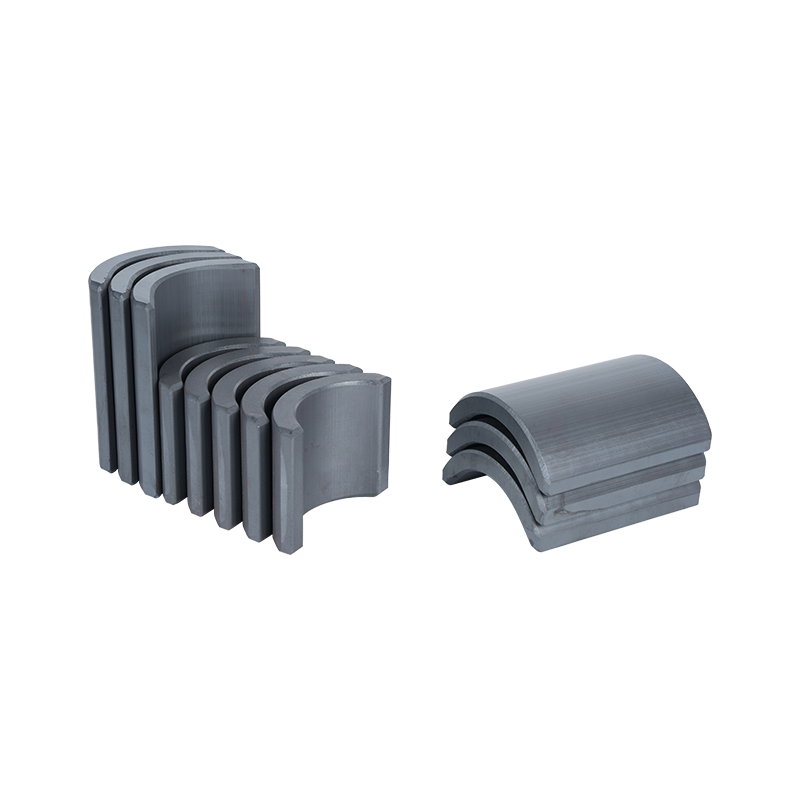

The integration of Cleaning Machine Ferrite Magnetic Tiles into existing cleaning equipment is a seamless process. These tiles can be easily attached to the cleaning heads of machines, ensuring that they are in direct contact with the surfaces being cleaned. As the machine moves across the surface, the magnetic tiles effectively capture and hold any metal particles, preventing them from being redistributed back onto the cleaned area.

The versatility of Cleaning Machine Ferrite Magnetic Tiles makes them suitable for a wide range of applications. In the food processing industry, they are used to ensure that production lines are free from metal contaminants, which could otherwise pose a risk to both product quality and consumer safety. Similarly, in the automotive sector, these tiles are employed to maintain the cleanliness of manufacturing facilities, reducing the risk of metal debris damaging sensitive machinery.

One of the key benefits of Cleaning Machine Ferrite Magnetic Tiles is their ability to enhance the overall efficiency of cleaning processes. By removing metal particles from surfaces, these tiles reduce the need for additional cleaning steps, such as the use of magnets to manually remove debris. This not only saves time but also minimizes the risk of human error, ensuring a higher standard of cleanliness.

The durability of Cleaning Machine Ferrite Magnetic Tiles is another factor contributing to their growing popularity. Made from robust materials, these tiles are designed to withstand the rigors of industrial cleaning processes, ensuring a long service life. Maintenance is also straightforward, with the tiles being easily cleaned and ready for reuse, reducing the need for frequent replacements.

The use of Cleaning Machine Ferrite Magnetic Tiles also brings environmental benefits. By reducing the need for chemical cleaning agents, these tiles contribute to a greener, more sustainable approach to industrial cleaning. This aligns with the growing global focus on reducing the environmental impact of industrial processes.

As industries continue to evolve and the demand for cleaner, more efficient processes grows, the role of Cleaning Machine Ferrite Magnetic Tiles is set to expand. With ongoing research and development, these tiles are expected to become even more effective, potentially incorporating additional features such as self-cleaning capabilities or the ability to target specific types of contaminants.

Cleaning Machine Ferrite Magnetic Tiles represent a significant advancement in the field of industrial cleaning. Their ability to attract and hold metal particles, combined with their durability, ease of integration, and environmental benefits, make them an invaluable tool for maintaining cleanliness and safety in a wide range of industries. As these tiles continue to be refined and improved, their impact on industrial hygiene is expected to grow, ushering in a new era of clean, efficient production processes.