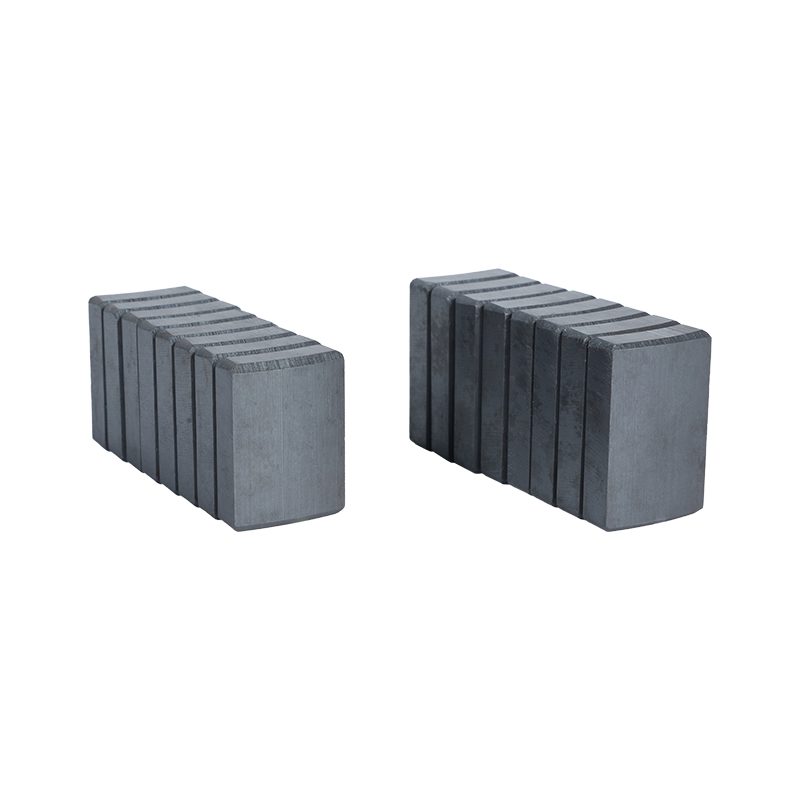

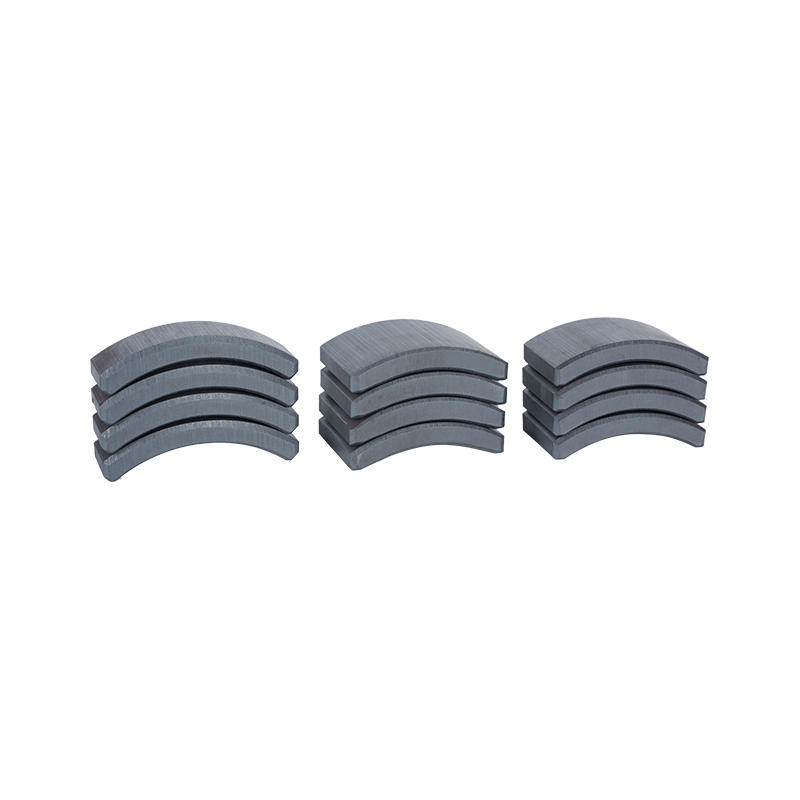

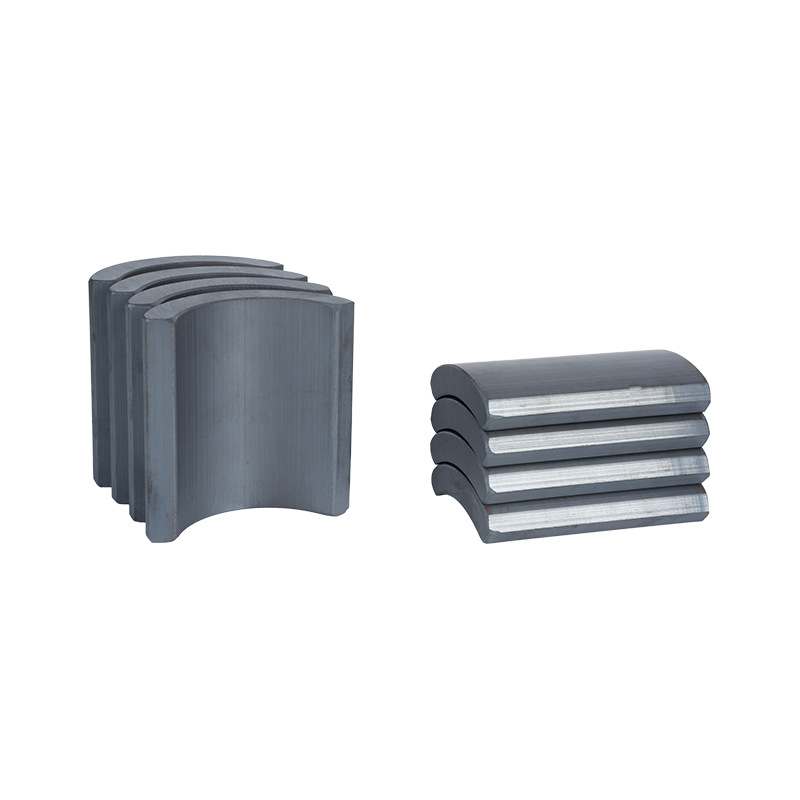

Dong Yang TianQi Magnetic Segment Co.,Ltd.(formerly Shuangyang Magnet Tile) is a professional enterprise specializing in the production of motor magnet tiles

Search by posts

Categories

Popular products

Contact Us

Industry News

By Admin

By Admin

High Performance NeFeB Magnets vs. Regular Magnets: What Sets Them Apart?

Magnets play a critical role in modern technology, from motors to electronics and even in medical equipment. However, not all magnets are created equal, and understanding the differences between types can help you choose the right one for your needs. NeFeB magnets, also known as neodymium magnets, are known for their high performance, particularly in strength and durability. In this article, we'll explore what sets high-performance NeFeB magnets apart from regular magnets and why they may be worth considering for certain applications.

What Are High Performance NeFeB Magnets?

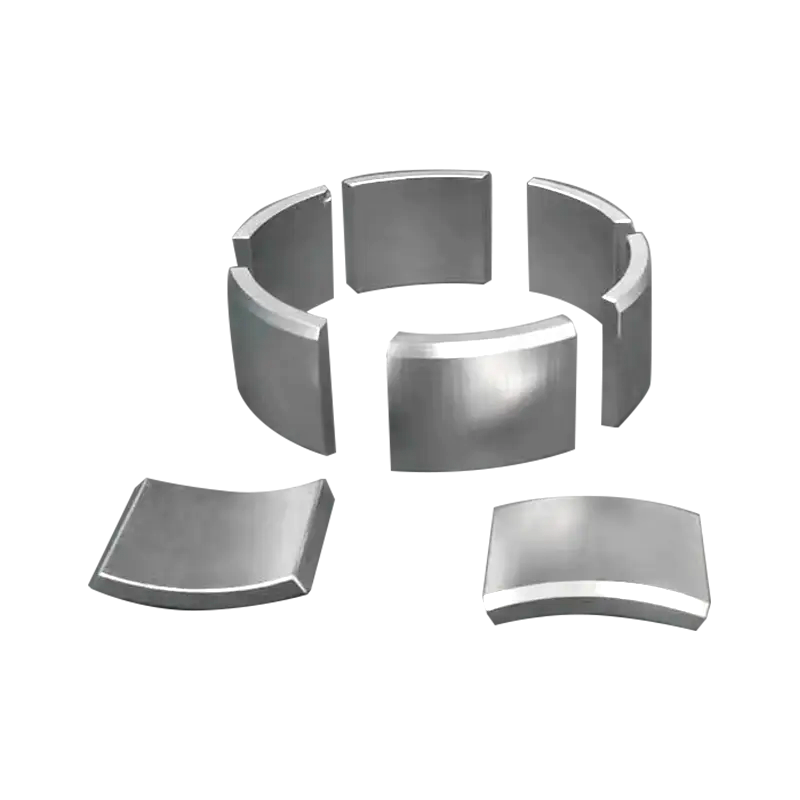

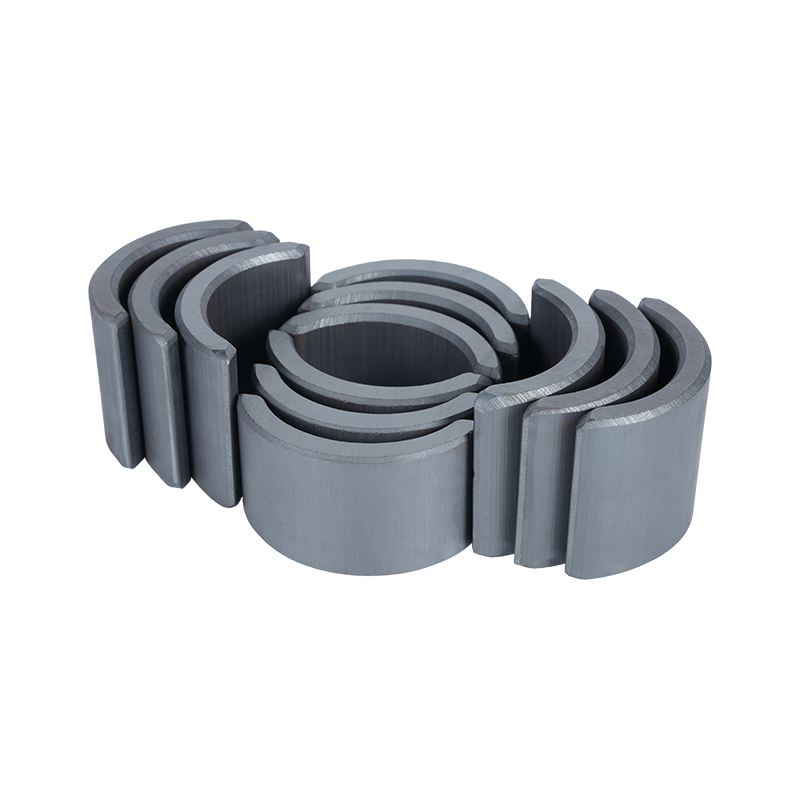

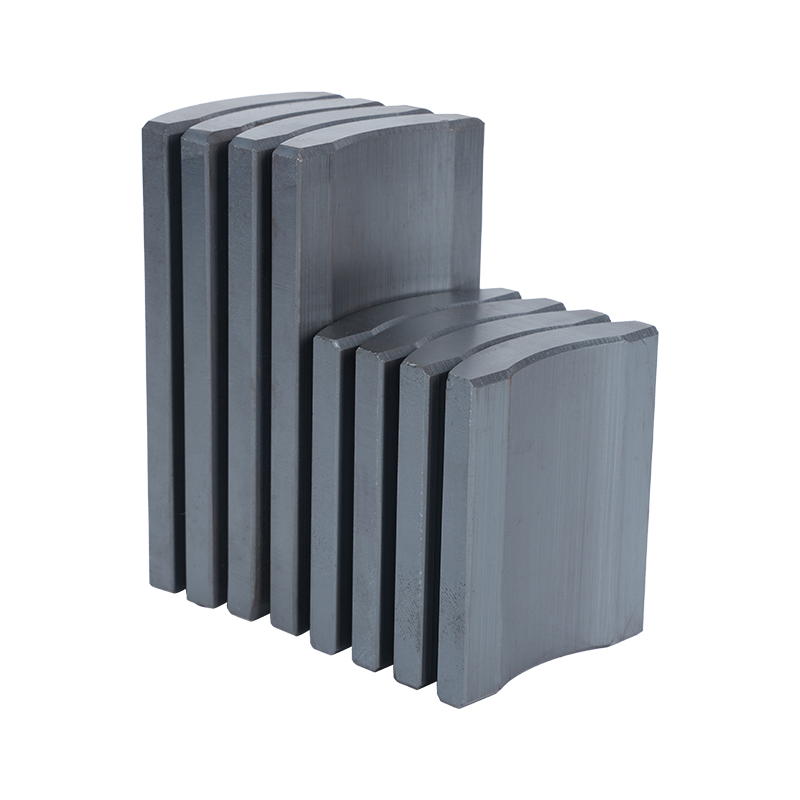

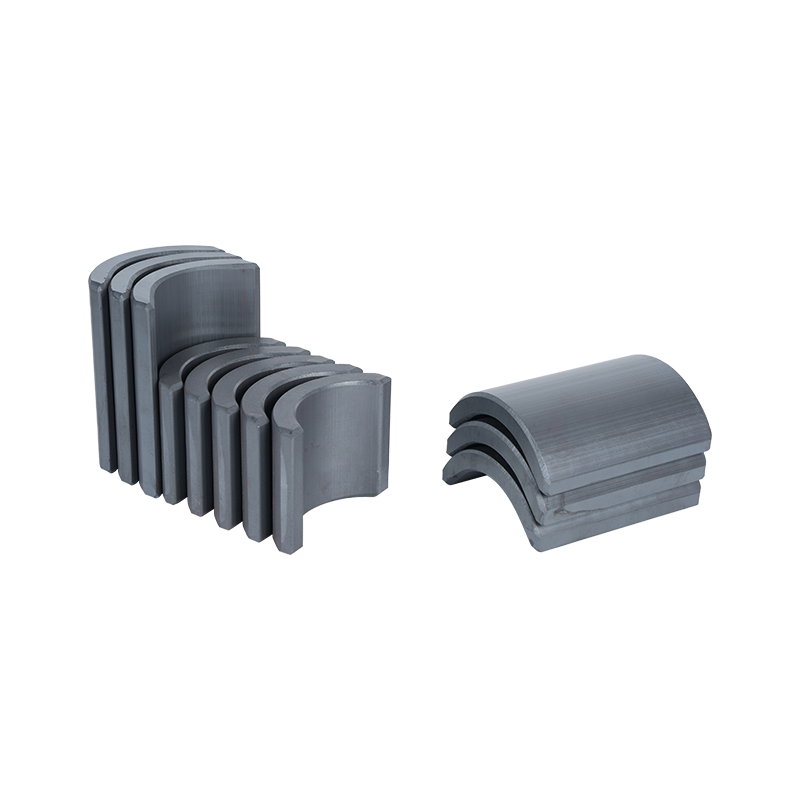

High-performance NeFeB magnets are composed primarily of neodymium, iron, and boron, resulting in an exceptionally strong and durable magnetic material. NeFeB magnets are often compared to traditional magnets like ceramic or ferrite magnets due to their magnetic strength and smaller size requirements. These magnets have become popular in industries where a compact, powerful magnet is required, such as in electric motors, computer hard drives, and various high-tech applications.

Magnetic Strength: The Key Advantage of NeFeB Magnets

One of the most notable benefits of high-performance NeFeB magnets is their intense magnetic strength. NeFeB magnets are considered some of the strongest permanent magnets available. Compared to regular magnets like ferrite or ceramic, NeFeB magnets offer a far stronger magnetic field, allowing them to generate more force from a smaller form.

For instance, in applications where space is limited, such as in miniature motors or audio speakers, high-performance NeFeB magnets can deliver substantial power without requiring a larger component. This strength allows manufacturers to design compact devices without sacrificing performance. In contrast, standard magnets may need to be significantly larger to achieve the same level of magnetic pull, which is impractical in certain industries.

Corrosion Resistance: Extending Durability

While standard magnets can be susceptible to corrosion, particularly in humid or harsh environments, high-performance NeFeB magnets are often coated with protective materials like nickel, epoxy, or zinc. This corrosion-resistant quality is critical in industrial applications where the magnet is exposed to moisture, chemicals, or varying temperatures. For example, in the automotive industry, where NeFeB magnets are frequently used in sensors and electric motor components, corrosion resistance is essential for long-term reliability and performance.

In contrast, regular magnets without such coatings may rust or degrade over time, reducing their lifespan and effectiveness. This added durability makes NeFeB magnets a smart choice for applications where environmental exposure is a concern.

Temperature Stability and Performance

Another benefit of high-performance NeFeB magnets is their stability under high temperatures. While they are not as heat-resistant as some specialized magnets like samarium cobalt, NeFeB magnets can typically withstand temperatures up to around 150°C (302°F) before their magnetic properties start to weaken. This temperature stability makes them suitable for many industrial and automotive applications where components may be exposed to moderate heat.

On the other hand, regular magnets such as ceramic or ferrite magnets may not perform as reliably under high temperatures. Their magnetic properties can weaken significantly, limiting their usefulness in high-temperature environments. For industries that require consistent performance across varying temperatures, high-performance NeFeB magnets often provide a more reliable solution.

Practical Applications of High Performance NeFeB Magnets

The unique characteristics of high-performance NeFeB magnets make them valuable in a range of industries. Here are some examples of where they shine:

Electronics and Audio Equipment:

NeFeB magnets are widely used in headphones, microphones, and speakers because of their compact size and strong magnetic field. They enhance sound quality and allow for smaller, lighter devices.

Automotive Industry:

Electric vehicles (EVs) and hybrid cars rely on high-performance NeFeB magnets in electric motors and sensors. Their magnetic strength contributes to the efficiency and durability of EV motors, where every ounce of weight savings matters for efficiency.

Medical Equipment:

In medical applications, high-performance NeFeB magnets are essential in devices like MRI machines and surgical tools. The magnets' precision and strength enable high-quality imaging and accurate tool movements, enhancing patient care.

Renewable Energy:

NeFeB magnets play a crucial role in wind turbines and solar panel positioning systems. Their strength allows turbines to operate more efficiently, generating higher energy output with fewer materials.

Are High Performance NeFeB Magnets Worth the Investment?

While high-performance NeFeB magnets typically come at a higher price point than standard magnets, their benefits often justify the investment, particularly in demanding applications. The increased magnetic strength, durability, and corrosion resistance make NeFeB magnets a choice for industries that require reliable, long-lasting performance.

If you're working on a project that requires a strong, compact magnet, or if environmental factors like moisture or temperature are concerns, NeFeB magnets are likely worth the additional cost. Their versatility across applications, from consumer electronics to heavy industrial equipment, highlights their value as a high-performance material. Regular magnets may suffice for low-demand situations, but in high-stakes environments, NeFeB magnets offer a level of performance that is hard to match.